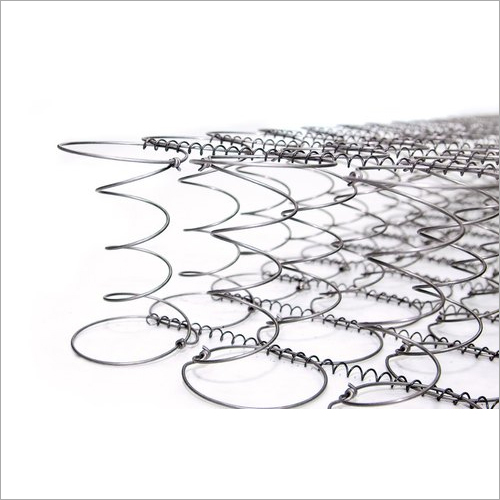

High Carbon Steel Wire Bonnell Spring

High Carbon Steel Wire Bonnell Spring Specification

- Usage

- Industrial

- Style

- Waved

- Load Type

- Extension

- Material

- Stainless Steel

- Wire Diameter

- Varies between 2.2mm and 2.4mm Meter (m)

- Product Type

- High Carbon Steel Wire Bonnell Spring

- Surface Finish

- Smooth and corrosion-resistant finish

- Fatigue Test

- Tested for prolonged usage and resilience

- Color

- Silver

About High Carbon Steel Wire Bonnell Spring

We are highly looked upon in this domain for manufacturing and exporting a wide array of qualitativeHigh Carbon Steel Wire Bonnell Spring is designed by our skilled workforce using the supreme quality materials sourced from the reliable vendors of the industry. This item is mainly utilized in mattress for offering relaxation to the person while sleeping. It is appreciated in the market due to its attributes like high quality and durability. We offer this Bonnell Spring without any delay.

Optimized Performance with High Carbon Steel

Our Bonnell springs are crafted using premium high carbon steel wire, ensuring durability and superior resilience. The waves in the spring design distribute load efficiently, contributing to extended service life and consistent performance in industrial environments. Each piece undergoes strict fatigue testing to guarantee reliability during long-term usage.

Superior Corrosion Resistance

The springs feature a smooth, corrosion-resistant finish tailored for harsh industrial settings. This surface treatment not only enhances longevity but also maintains structural integrity in the presence of moisture or chemicals. Clients benefit from reduced maintenance and fewer replacements over the products lifespan.

FAQs of High Carbon Steel Wire Bonnell Spring:

Q: How are High Carbon Steel Wire Bonnell Springs manufactured for industrial use?

A: These springs are produced using high carbon stainless steel wire with a diameter ranging from 2.2mm to 2.4mm. The waved design is formed through precise machinery, followed by a smooth and corrosion-resistant finishing process to optimize durability and ensure consistent extension performance.Q: What benefits do the waved style Bonnell springs offer in industrial applications?

A: The waved style enhances the springs flexibility and load distribution, improving resilience against repeated extension and compression. This results in superior fatigue resistance and prolonged operational life, even under demanding usage conditions.Q: When is it recommended to use Bonnell springs with a corrosion-resistant finish?

A: It is advisable to use these corrosion-resistant Bonnell springs in environments where exposure to moisture, chemicals, or varying temperatures could affect unprotected metals. The finish safeguards against rust, guaranteeing reliable performance over time.Q: Where can High Carbon Steel Wire Bonnell Springs be applied in industry?

A: These springs are widely used in machinery, automotive, manufacturing, and equipment assemblies where durable extension springs with strong fatigue resistance are required. They are suitable for any setting demanding longevity and consistent load support.Q: What is the process for conducting fatigue tests on these Bonnell springs?

A: Fatigue testing involves subjecting the springs to repeated cycles of extension and compression under defined loads. This assessment ensures that the spring maintains its shape, elasticity, and performance standards over time, verifying its suitability for prolonged industrial usage.Q: How does the smooth and corrosion-resistant finish benefit the springs functionality?

A: This specialized finish prevents the formation of rust and surface irregularities, preserving both the springs mechanical properties and appearance. It reduces maintenance needs and helps maintain optimal load capacity throughout its service life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email